Quite simply, at Furina Powerboats, we choose to use only top-end products, partners and techniques to deliver high-quality, expertly crafted custom powerboats to our clients.

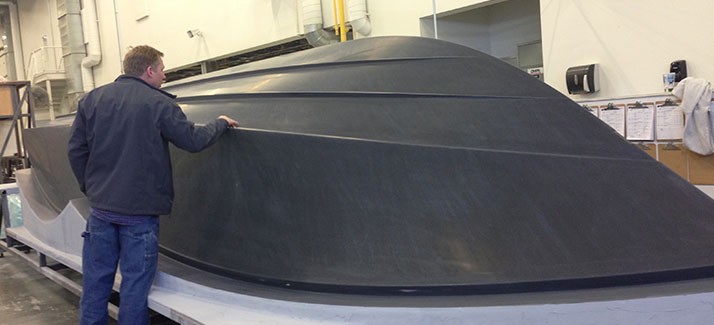

Starting with a great foundation is key. That’s why we develop Furina Powerboats’ hull, deck and small parts plugs with our partners using a CNC machine process. The plugs are created on a CMS Poseidon 5-axis machine optimized for durability, reliability and precision. Tolerances with this process are very tight, certified to an overall volumetric tolerance of 0.1 mm or .004”. The completed plugs are sanded using an 800-grit method for a mirror smooth finish. This time consuming method translates into a better final surface from plug to mold to shell – powerboat craftsmanship perfection.

Also part of the powerboat craftsmanship, Furina Powerboats’ hulls and decks are constructed of fiberglass-resin composite using a vacuum-infusion process (VIP) – in lieu of the more popular hand-layup. The VIP process is ideal for producing Furina’s complex profile. This process produces a higher fiberglass-to-resin ratio for improved strength, with minimal-to-no voids in the finished laminate. Additionally, because the vacuum removes air, excess resin and volatiles, a stronger bond is produced between layers. There is also excellent control and consistency in wall thickness, from part to part and boat to boat. What’s more, the vacuum-infusion environment is cleaner, with very low VOC air pollution.

Furina uses Ashland Maxguard™ gelcoats for minimal shrinkage, unsurpassed weathering/UV resistance and excellent yellowing and blistering resistance.

VOLVO POWER

Volvo Penta’s next generation engines use modern technology and advanced design to power Furina’s powerboats. Volvo engines provide improved acceleration, impressive mid-range response, reduced fuel consumption, reduced emissions and smooth operation. All Volvo Penta products – propellers, drives, engines, controls, instruments, accessories, etc. – are developed for perfect interaction and optimal performance. This means you have one single contact for service and support.

QUALITY CONTROL

Furina’s powerboats are completely assembled by detail-oriented experienced craftsman. Throughout the build, parts and processes are reviewed by principal Ross Hartman to ensure quality from assembly to component integrity.

As a client of Furina Powerboats, you will appreciate the beauty of Furina, as well as her fine powerboat craftsmanship and high quality components – for years to come.

To start building your Furina now Go To> BUILD YOUR BOAT

Furina Powerboats

P.O. Box 1311

Belchertown, MA 01007

800-882-1795

info@furinapowerboats.com

Connect with us on Social Media:

![]()

![]()

![]()

![]()

![]()